The fastest and easiest way my seem to be also the simplest answer.

YES - Bump up the hydraulic pressure in the system. Adjust the pressure relief valve.

But is that relay the answer? What dangers lurk in bumping up the pressure on any machine?

Well you be the judge and consider the evidence presented.

The Importance of Check Valves in Hydraulic Systems

Please click on the image below and read a very informative article explaining the need to respect the pressure relief valve and not mess with it. Full Stop.

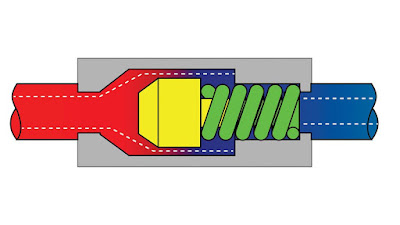

In the next image consider all the hydraulic seal that will come under additional pressure after we have bumped up the system pressure.

Here we have the rod collar an the piston from inside the hydraulic cylinder.

Notice the damage to the O rings and pressure seals.

The O rings look like they are perished, or got pinched or damaged during assembly.

Not the case.

In this photo the O rings look like they have had heat or fire damage.

Not the case.

Another shot.

Event the tough pressure seals on the piston have degraded and have splits and cracks in they.

New seals fitted and fitting the piston to the rod.

This is how seal should present.

Case Lesson - Keep to the manufactures specifications.

Keep hydraulic system pressure the designed and save yourself heaps of time and money.